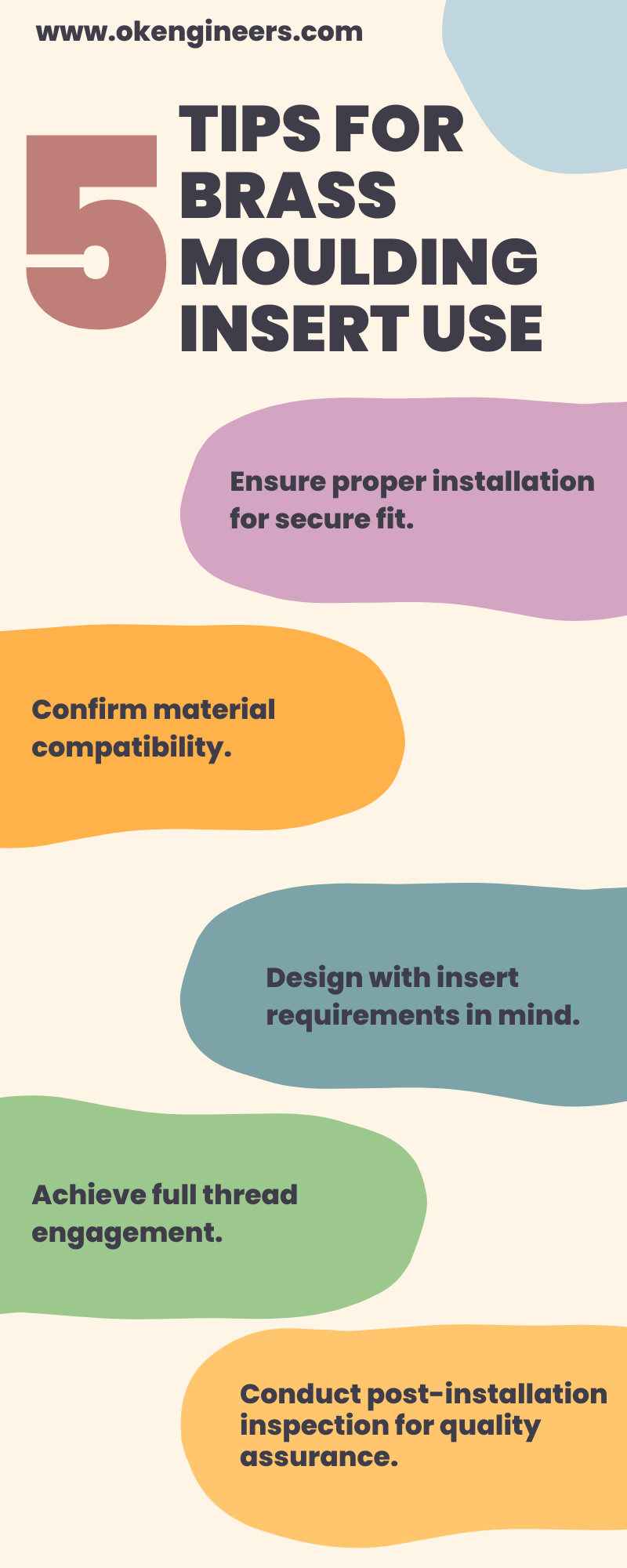

5 Tips For Brass Moulding Insert Use

Proper Installation: Ensure that the Brass Moulding Insert is installed securely and correctly within the moulded part. This includes aligning the insert properly and applying the appropriate force during installation to prevent any damage to the insert or the surrounding material.

Consider Material Compatibility: Before selecting a brass moulding insert, consider the compatibility of the brass material with the base material of the moulded part. Brass inserts are typically suitable for use with plastics, composites, and other non-ferrous materials. However, it's essential to verify compatibility to prevent any chemical reactions or degradation over time.

Optimal Design Considerations: Design the moulded part with the brass insert in mind, ensuring adequate space and clearance for insertion. Additionally, consider the design of the insert itself, including its shape, thread type, and length, to ensure it meets the specific requirements of your application.

Proper Thread Engagement: When using brass moulding inserts with threaded connections, ensure that the threads of the insert engage fully with those of the mating component. Proper thread engagement is crucial for achieving a strong and reliable connection, preventing loosening or stripping of the threads over time.

Post-Installation Inspection: After inserting the brass moulding insert into the moulded part, conduct a thorough inspection to verify proper alignment, fit, and integrity. Check for any signs of damage or irregularities that may affect the performance of the insert or the final product. Address any issues promptly to ensure optimal functionality and durability.